3D Printing Industry are at the 3D Medical Expo 2017 this week to see previews of new 3D design software due for release later this year.

Making prosthesis adjustments easier

One of the most inspiring software developments at the conference is from Latvian company WiDE (We Improve Device Experience).

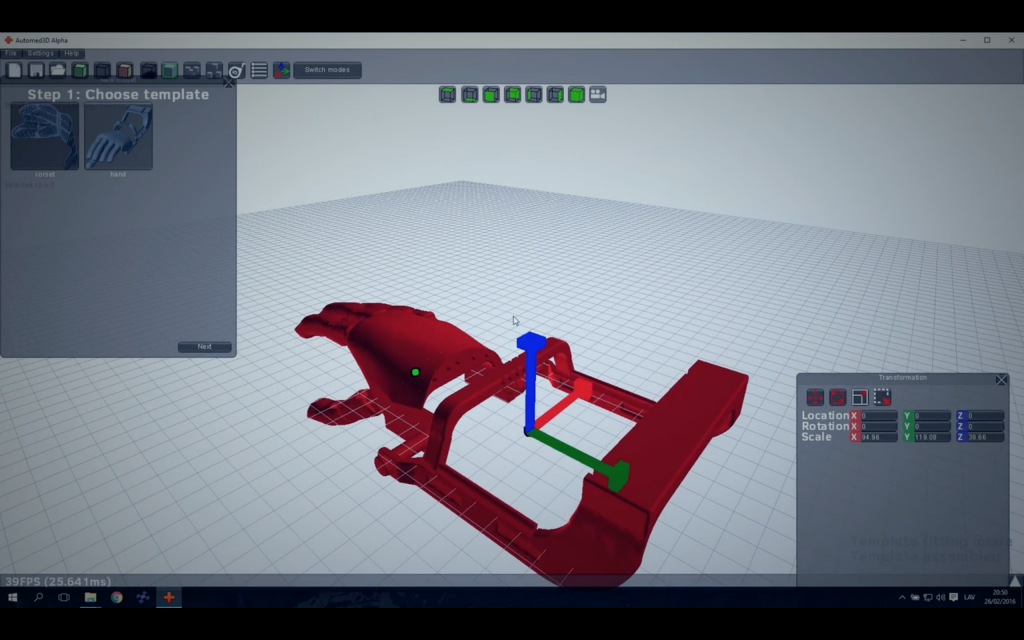

There is an influx in hobbyists using 3D to make custom prosthesis. What WiDE orthotist and prothetist Fricis Pirtnieks points out is that though the files are generally shared as open source, a person would have to have some 3D design experience to adjust the design to meet personal specifications.

WiDE software was developed as a solution to this with tools that are easy to use.

New software from 3D Systems and Renishaw

3D Systems’ latest development in 3DXpert is designed to bypass the sometimes tricky .stl file format, and integrates slicing for 3D printing into one whole program. Hari Sridharan, Director of Application Engineering and Training took 3D Printing Industry through the software during IMTS last year, you can read more about the 3D printing and design software here.

For CAD of medical implants, Renishaw demonstrated the ADEPT project. The basic concept behind the software is again that users don’t have to be an engineer in order to design patient specific plates or surgical guides.

A 3D scan of a patient’s skull is loaded into ADEPT, and the program detects the live bone. After that the user, typically a surgeon, can simply plot points around the area in need in a similar way to drawing a polygon in Photoshop.

This demo is the first preview of the software that has been in development for 3 years, funded in part by innovation incubator Innovate UK.

Demo of Renishaw’s ADEPT software. Photo via Erick Ramírez on Twitter

Taking CAD for granted

As the so-called “unsung hero” of the 3D printing trifecta (software, hardware and materials) CAD one of the key ways to introduce new adopters to the process. Ultimately, 3D printing should eventually be able to take the 3D design process for granted when producing a product, much the same as in 2D printing onto paper.

For more previews of software for 3D printing, sign up to the 3D Printing Industry newsletter.

We’re also looking for the best software and 3D designs at the 3D Printing Industry Awards. Nominate your favourites here.

[Source:-3D Printing Industry]